With the painted inlet pipe in my hand I can now continue to assemble the engine. On this task I was the most keen on.

The most difficult task in my point of view is to sleeve the cylinders over the pistons. Three hands would be perfect - one hand to compress the piston rings, one hand to hold the piston and a third hand to sleeve the cylinder over the piston - step by step. Yes, I know, that there is a tool for compressing the piston rings, it is even in my tool shack, but I found this way more convenient. You just need to be careful, not to pinch your fingers between piston and cylinder.

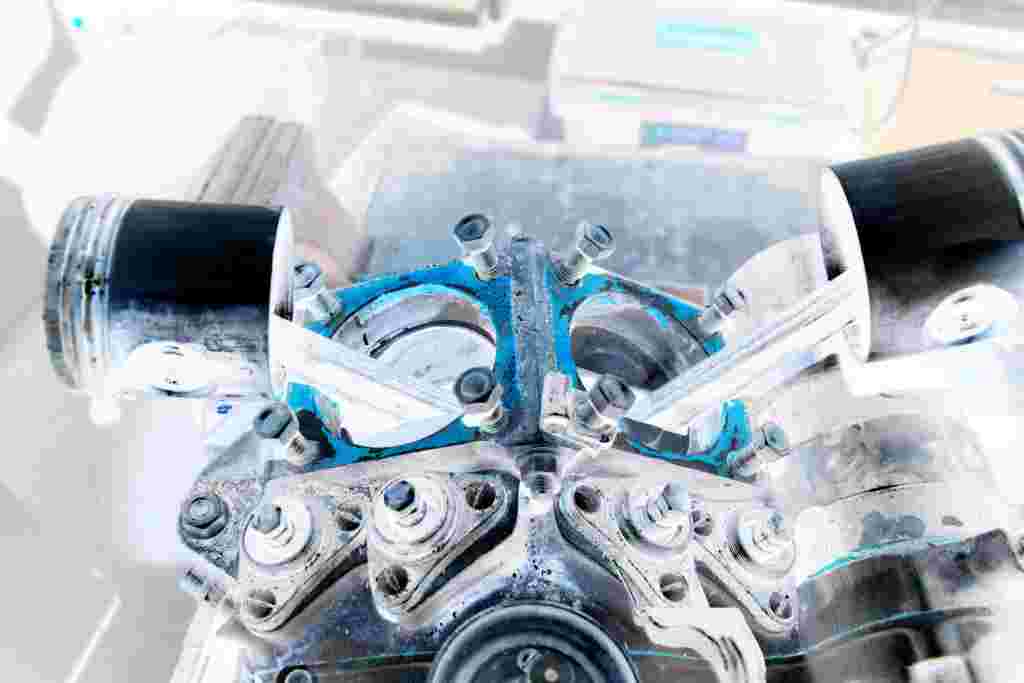

In addition you need to align the cylinders, that the inlet pipe can be mounted tight. This task - for both cylinders - needs to be done within a few minutes, because I covered the cylinder gaskets slightly with sealing compound.

Adjusting the valve tappet screws isn't too difficult.

As long as the cylinder heads are not mounted, the circuit breaker is more easier to assemble. You can easily detect the position of the flywheel and pistons for a correct adjustment of the static ignition timing.

Next step is the assembly of the carburetor. I installed a new brass float lever and made the required adjustment. The old one already passed over the Jordan.

After I mounted the cylinder heads, the engine is now completely assembled. Yeah, such an assembled engine is a really nice looking thing. No comparison against the previous look.

After months of disassembling, this is a major step forward. But if the engine will work as expected, we will see...