Finally. After I prepared my working place in the cellar - in the garage it was freezing cold - I started to detach the engine from the frame an carried the oily piece into the comfortable heated cellar.

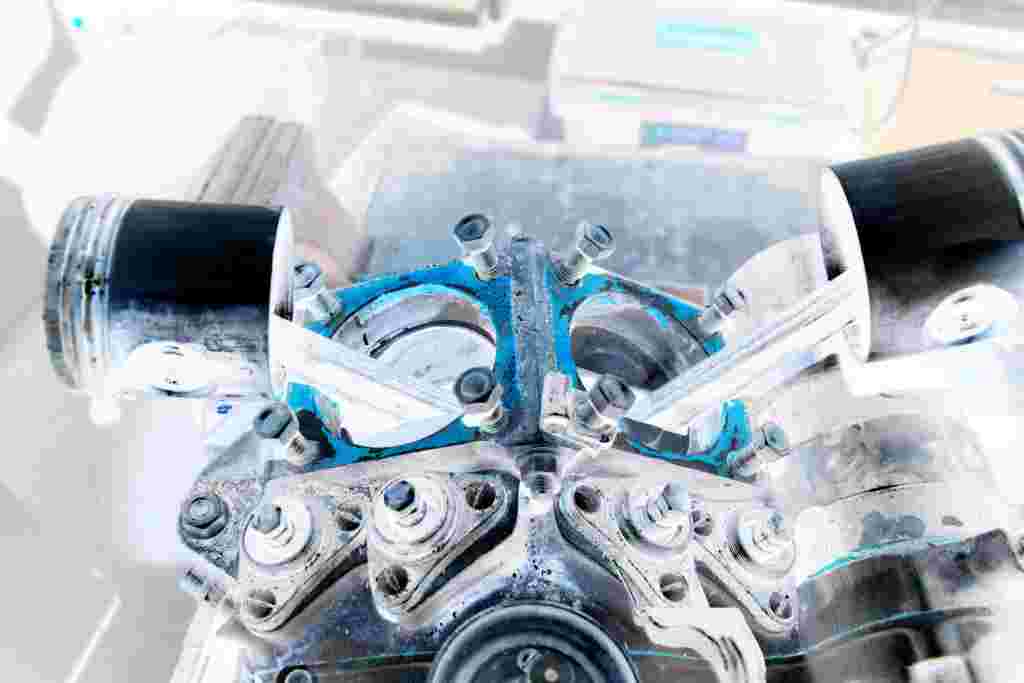

With detached cylinder heads, significant oil carbon was visible on the pistons. Looking to the carbon trails, there must be some oil leakages. This explains the heavy oil smoke during the breakdown in September 2012.

After I disassembled the rear cylinder, I recognized broken piston rings. This explains the loss of engine power.

Usually I might stop at this point with disassembling the engine, if the connecting rods wouldn't had large end play - sidewards! This also resulted in the scratches on the piston skirt.

When I measured the cylinder bores it become obvious, that just replacing pistons and piston rings will not do the job.

Therefore I continued to completely disassemble the engine. Disassembling the flywheel is a little bit tricky - in special if you didn't this before. I was very uncertain where and how tight I can hit the flywheel with which type of hammer. Finally the flywheel refused to resist anymore.

Honestly it wasn't clear to me which kind of project I have started. Day by day I opened more and more issue tickets - and I didn't solved a single problem until now. Anyhow I targeted to repair the engine latest in April and have a ride in June.

At least that's the plan! It is always good the have a plan!